4. Computer controlled cutting¶

Class site¶

Class video¶

Fab-20190206B_Review02: computer-aided design

Fab-20190206D_Lesson03: computer-controlled cutting

video

Assignment¶

group assignment :

characterize your lasercutter, making test part(s)

that vary cutting settings and dimensionsindividual assignment :

cut something on the vinylcutter

design, lasercut, and document a parametric press-fit construction kit,

accounting for the lasercutter kerf,

which can be assembled in multiple ways

(1)Laser Cutting¶

Learning outcomes¶

- Demonstrate and describe parametric 2D modelling processes

- Identify and explain processes involved in using the laser cutter.

- Develop, evaluate and construct the final prototype

Have you?¶

- Explained how you parametrically designed your files

- Shown how you made your press-fit kit

- Included your design files and photos of your finished project

(2)Vinyl Cutting¶

Learning outcomes¶

- Identify and explain processes involved in using this machine.

- Design and create the final object

Have you?¶

- Explained how you drew your files

- Shown how you made your vinyl project

- Included your design files and photos of your finished project

For Japanese¶

Final Project Tracking Page¶

Week1のスケッチ、Week3のCADで作ったFinal Projectの一部を使って、Final Project Tracking Pageを作り、毎週書き足しましょう

レーザー加工機使用時の注意¶

- never leave laser under unsupervise

- presessionで説明したことを守りましょう

Group Assignment¶

- ラボサイトにまとめる予定でしたが、各人のサイトにGroup Assignmentで取り組んだ様子と結果、学んだことなどを書くことになりました

- 受講生全員が参加していることをインストラクターが確認します

- FAQ What does characterise mean?

- Describe/understand the nature and features (of your particular laser cutter)

- Inkscapeのclone機能だけでは、パラメトリックとしては不十分

-

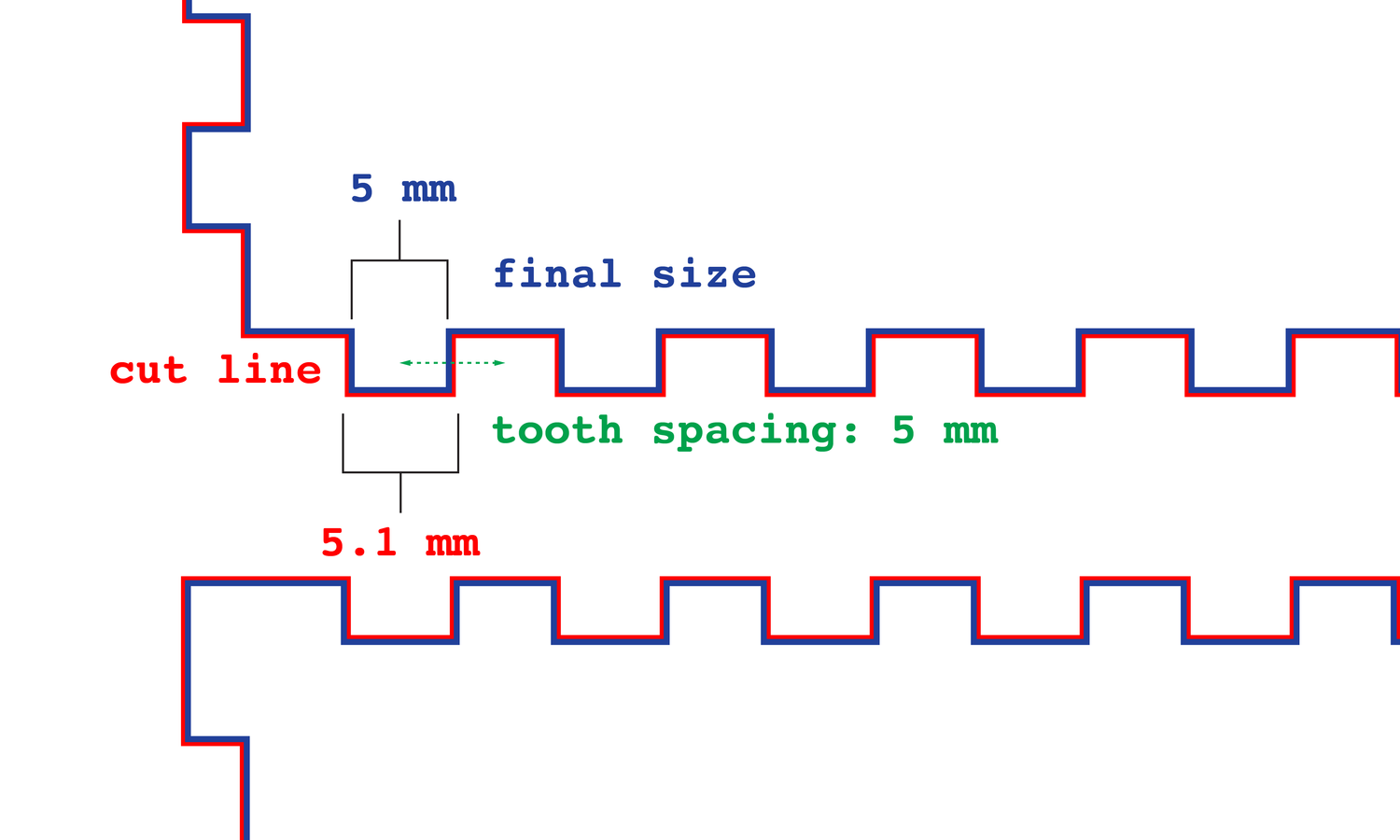

kerf: 切り口の幅

-

ref. http://www.connorkirk.com/blog/2015/12/14/compensating-for-laser-cutter-kerf

-

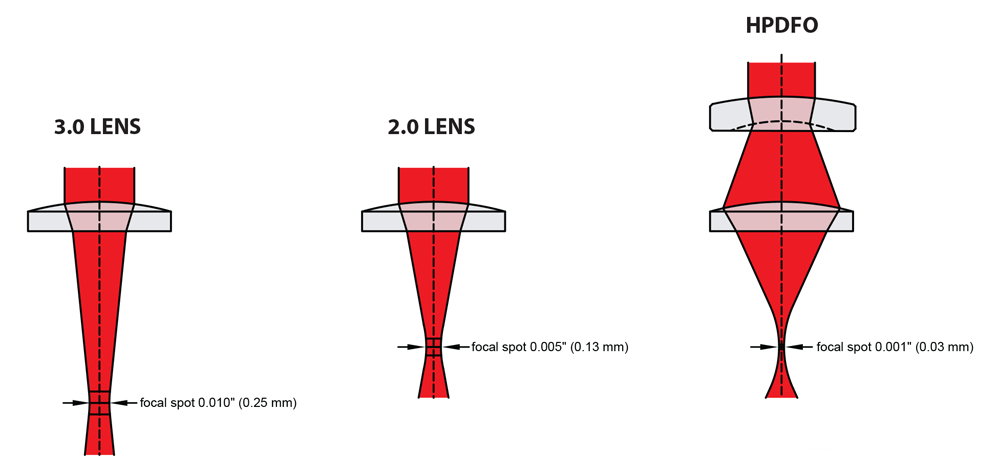

- spot size: 0.005” (0.13mm)

- spot size: 0.005” (0.13mm)

-

class: kerf 0.010” (0.254mm)

-

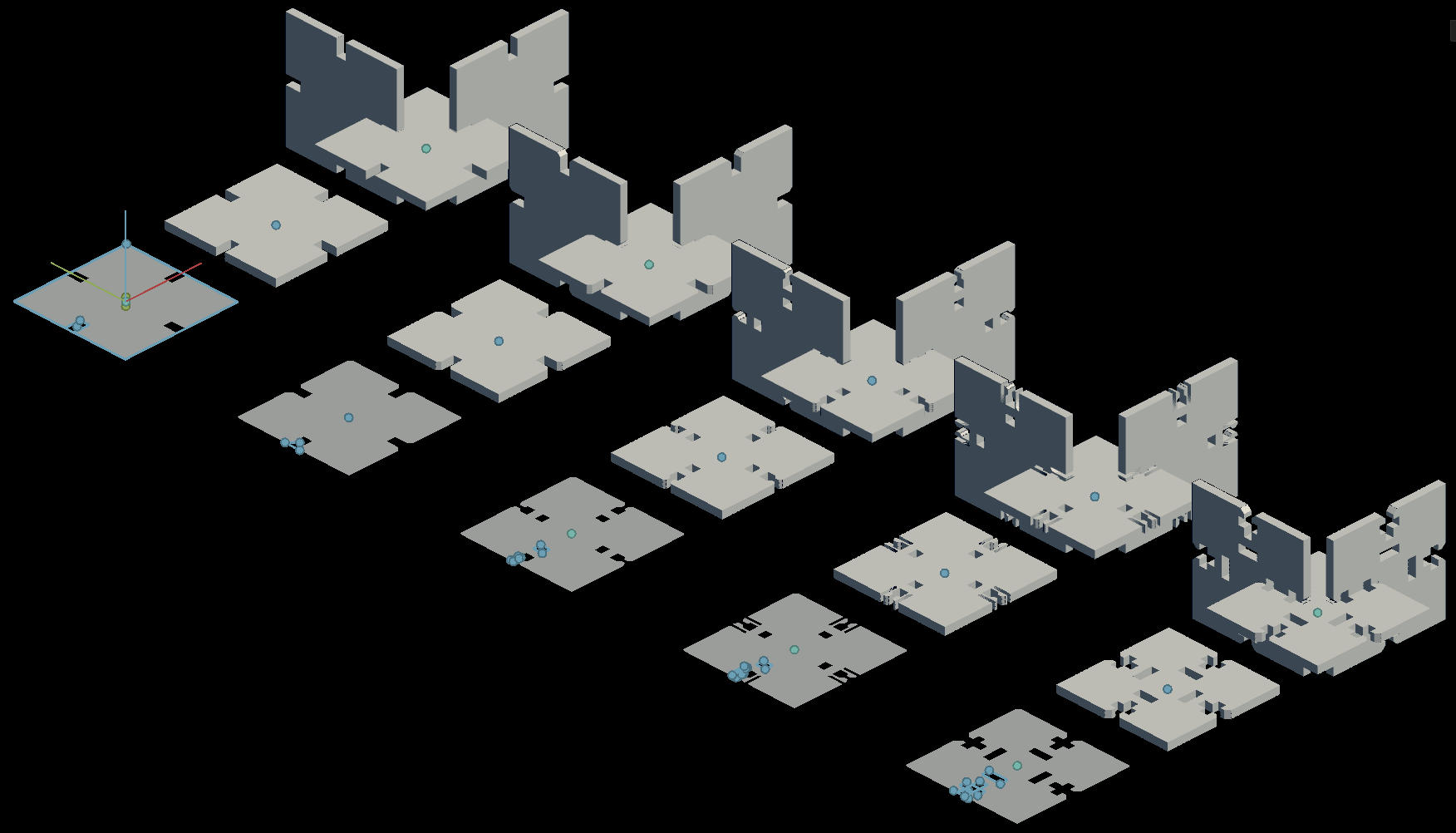

class: FreeCAD video GIK.mp4

- FreeCAD file GIK.fcstd

-

方法

- 使う材料において、適切なレーザー加工機の出力パラメーターを出す(Power, Speed, DPI)

- 実際にkurfを測る

- デザイン寸法の分かるものを切って、カットしたもののサイズを測り、差からkurfを求める

- Combをつくってフィットする寸法を見つける

- comb

- FabLab平塚道用先生作: Kerf Check Parts Generator

Assignment¶

-

Laser Cutter

- 得られたkerfの値も含めたパラメトリックデザインのpress-fit constructin kitを作る

- multiple waysに組み立てられるものであること

- simple slotではなく、chamfer(面取り)も加えましょう

- 材料: ダンボール A3 3mm厚

- アクリルやMDFと違い、向きで特性が異なるので注意

- 細くなっている箇所は燃えます

- Fusion 360 > Change Parameters > Sketch

- Fusion 360からsvgを便利に書き出せるAPP Shaper Utilities

-

Vinal Cutter

- test cut each time

- silhouette CAMEO and Silhouette Studio Ver3 or Ver4

- Make:

- Laptop Sticker

- Sand Blast -> 関内はこれをやります

Extra credit¶

- Flatではないものを作る

- Inkscape Extention

- インストール方法: download and unpack the archive file. Copy the files into the directory listed at Edit > Preferences > System: User extensions. After a restart of Inkscape, the new extension will be available.

- Inkscape Extention

- Trotec: Download CorelDRAW and PDF

読みましょう¶

- FabAcademy-Assessment: 6.Computer-Controlled Cutting

- FabAcademy-Tutorials: 4.1-4.5

Useful links¶

- Inkscape Extentions

For Next Week¶

- Monday 9:00 EST, 23:00 JST

- Recitaion: projects

- Tuesday Time:

- Asia Regional Review: 13:00-14:00 JST and 22:00-23:00 JST

- 13:00-14:00 JSTの参加者が少ない

- videoconference

- conference for meetings: https://bluejeans.com/fabevent/1248 予定

- Wednesday 9:00 EST, 23:00JST

- videoconference

- https://bluejeans.com/academany/2486 ~200 ports

- Electronics Production

- videoconference

assignment¶

group assignment:

characterize the design rules for your PCB production processindividual assignment:

make an in-circuit programmer by milling the PCB,

check if you can program it,

then optionally try other PCB processes

ATtiny45

Sean Tomás Jonathan Brian Zaerc

ATtiny44

Ali Valentin Bas Andy David

hello.ISP.44.cad board components traces interior

hello.ISP.44.res.cad board traces interior

inventory microcontroller crystal USB connector ribbon connector Zener diode jumper

firmware.zip programming

USB timing