8. Computer controlled machining¶

Class¶

Assignment¶

group assignment:

test runout, alignment, speeds, feeds, and toolpaths for your machine

individual assignment:

make (design+mill+assemble) something big

Previous year¶

Assesment¶

Learning outcomes¶

- Demonstrate 2D design development for CNC production

- Describe workflows for CNC production

Have you?¶

- Explained how you made your files for machining (2D or 3D)

- Shown how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)

- Described problems and how you fixed them

- Included your design files and ‘hero shot’ photos of final object

FAQ¶

- How big is big?

- Answer: Big enough to show you understand many of the possibilities of CNC machining - drill, pocket, dogbones, nesting, etc.

- Does it have to be wood or wood products?

- Answer: No. But the lab is only responsible for providing you with a full size wood board.

Schedule¶

- 3/14(土)

- local session

- デザイン

- ソフト VCurve or Cut2Dの使い方

- 3/15(日)

- 新横浜8:21-(ひかり503)-9:27浜松9:43-(東海道本線)-9:48高塚 -> 北口ロータリー

- 東京8:03---------------9:27浜松

- 金券ショップ@関内

- 材料は当日ホームセンターカインズホーム(雄踏店)に買いに行く

- 本館 9:00~20:00

- 資材館 7:00~20:00

- 3x6板 x2(group用,individual用)

- カインズホーム(雄踏店)合板取り扱い品一覧

- ソフト

- CNC

- ZN1325

- シャンク径6mm(6.35はなし)

- hamamatsu students

Endmill¶

種類¶

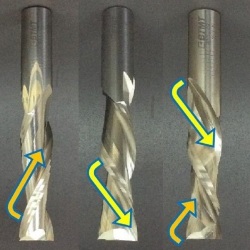

※写真は左から「アップカット」「ダウンカット」「アップ+ダウンカット」

ref.BTMT

- Upcut

- Downcut

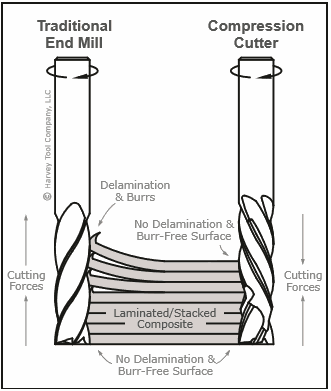

- Compression(Up and Down cut)

-

- CONVENTIONAL MILLING VS. CLIMB MILLING

- Climb Milling Vs. Conventional Milling: 12 Key Differences Machinists Must Know

- COMPRESSION CUTTER FOR COMPOSITES

- ref.[THE CORRECT WAY TO SETUP A COMPRESSION END MILL](https://www.stepcraft.us/blog/blog-1/post/the-correct-way-to-setup-a-compression-end-mill-8)

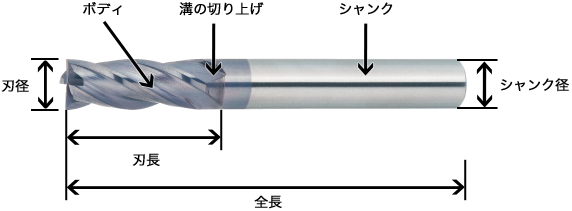

形状¶

ref.misumi

- Monotaro:コーティング

my endmill¶

- Shank Diameter: 6.35mm(1/4in)

- Shaper

- 1/4” Up-Spiral Router Bit

- 1/8” Up-Spiral Router Bit

- Engraving Router Bit 60°

- ONSRUD

-

TOOLS.GR

-

Shank Diameter: 6mm

- HOZLY 6X25mm アップ&ダウン カット2 スパイラルフルート

- Yiteng アップ&ダウン スパイラルフルート 6x6mm 4枚刃

- 6 mm V ビット 60 90 120 150 度

- 6 mm 60/90/120/150 度 V 溝ビット

- 6 mm ターボトムクリーニングルータービット

corret¶

- 6mmと6.35mm共用不可

- Spring Collet chuck

- Festool 488760 SZ-D 6/of 1000 Replacement Collet-6mm, Multi-Colour

- リョービ コレットチャック 1/4インチ トリマ用

材料¶

- 3x6板 910mmx1820mm

- Group Assignment 1枚、individual Assignment 1枚

- 個体差がある(2枚が同じ厚みとは限らない)購入時に測る?ノギス持参?

To Do¶

Safety¶

- glasses, shoes, clothes, hair, gloves

- 関内にあるものは持っていく

group assignment¶

- CNCの特性を知る

- ref.fablabtrivandrum 2018

- ref.oshanghai 2019

- runout

- 回転体の半径方向の振れ > エンドミルの振れ

- 刃径6mm vs 削り跡の幅

- 軸がぶれていると大きくなる

- alignment

- 度、向き、位置など機械構造の歪み

- 四角を切って、対辺が平行か、直角かを測る

- speeds

- 主軸速度(rpm)

- ディフォルト:12,000rpm(TechShop)

- 10,000-12,000-14,000 rpm

- 深さ(刃径と同じ)、速度固定で、rpmを変えて比較する

- feed rate

- 送り速度(mm/s)

- ディフォルト:1in/s(TechShop)

- 17-25-50? mm/s

- 深さ(刃径と同じ)、rpm固定(上記)で速度を変える

- toolpath

- climb, conversional

- Tolerance

- 交差 > kerf, offset

- comb

- 板厚:パラメトリック(測定値、カタログ値は参考のみ)

- スリット:オフセットを求める

individual assignment¶

- Design

- 2D, 2.5D

- parametric

- joint

- Dogbone Filets

- V-bit engrave

- Prototyping

- laser cut

- 設計15mm厚 > 3mm厚(=1/5 Scale)

- Cut

- Air cut

- Assemble

- sanding

(# Useful Links¶

- opendesk¶

Next week¶

- Monday Recitation 23:00-24:00

- debugging

- Tuesday Asian Regional Review 12:00 & 21:00

- 12:00-: zoon http://fab.academany.org/2020/video.html

- 21:00-: zoom or bluejeans Bluejeans.com/u/fablab/1248

- Wendnesday Class 22:00-1:00

- Embedded Programming

- assignment

group assignment:

read a microcontroller data sheet program your board to do something,

with as many different programming languages

and programming environments as possible

individual assignment:

compare the performance and development workflows for other architectures